The respected Comrade

"To develop fish farming is one of the important ways to increase the supply of fresh fish to the people."

Bottom center drain circular tanks in which water is injected tangentially to the tank wall are widely used in aquaculture. However, the no-slip condition that exists between the primary rotational flow and the tank's bottom and side walls creates a secondary flow. With this flow pattern at the tank bottom and tank surface, a torus-shaped region about the center drain can become an irrotational lower velocity zone.

Aquaculture tank hydraulics are mainly dependent on the tank geometry and the properties of water inlet and outlet. Many works were devoted to improve the tank hydraulics by making good use of the water flow pattern. Some researches on water nozzle designs in circular tanks showed that configurations with a vertical pipe containing evenly distributed nozzles produce more homogeneous flow distribution, compared to the inlet designs with a single point source. Rotational velocity about the perimeter of circular tanks is strongly dependent on the impulse force of water flow injected tangentially into the circular tank.

Recent works on the hydraulics in the fish culture tanks show a tendency to focus more efforts than ever before on nozzle parameters such as inlet and/or outlet placement, nozzle arrangement and injection flux as well as tank geometry. One of the most fundamental objectives of all hydraulics research in the fish culture tanks is to minimize the volume of low velocity zone (VLVZ) in order to optimize the utilization of the water and the available space in the tanks. But, mathematics-friendly methods, such as statistical optimization method, which is widely used in science and engineering, are rarely used in aquaculture tank designing. Our work focuses on the minimization of the low velocity zone in a bottom center drain tank based on experimental planning and computational fluid dynamics.

Model validation was carried out by comparison with measurements. The results show that the low velocity zone can be reduced in a measure by the proposed method. The results show that the nozzle pipe position is one of the most important factors in controlling VLVZ. Its optimal position might be related to the golden ratio on the periphery-side semi-radius. The particle tracking experiments shows a possibility to improve the self-cleaning capability of tank by adjusting the nozzle pipe position.

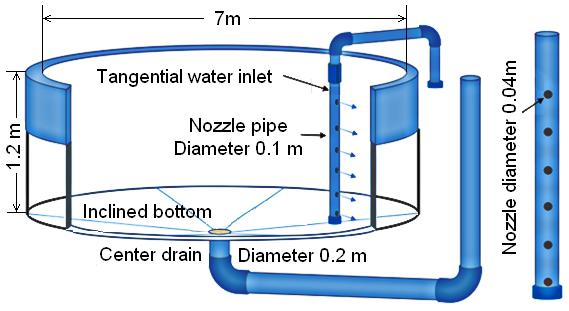

Geometry model of the tank and the water inlet are shown in Figure. The water inlet is a single vertical pipe with 6 nozzles. Every nozzle has an identical injection speed of 0.67m/s which is explained below.

It should be mentioned that the results and conclusions in present work might be appropriate to only circular tanks with diameter of about 7 m. Future research will be focused on designing a bottom double drain circular aquaculture tank (combined center-eccentric) in an optimal way and on designing the tanks with the movable nozzle pipe toward center drain.

The research result has been published in the journal of "Journal of the world aquaculture society"(2021, Vol. 52, No. 2) under the title of "A method for minimizing the zone of low water flow velocity in a bottom center drain circular aquaculture tank"(https://doi.org/10.1111/jwas.12792).