Our country has rich deposits of siderite, the main component of which is ferrous carbonate.

When we use siderite for the production of iron, we have to convert FeCO3 to Fe3O4 by roasting, and concentrate it magnetically. Magnetic roast-magnetic concentration is considered as the most effective technique in dealing with siderite. But this technique is not introduced in a wide scale because it is not so high in magnetic roast effectiveness with too much thermal energy, polluting substances and high cost as well.

The researchers of the Faculty of Chemistry,

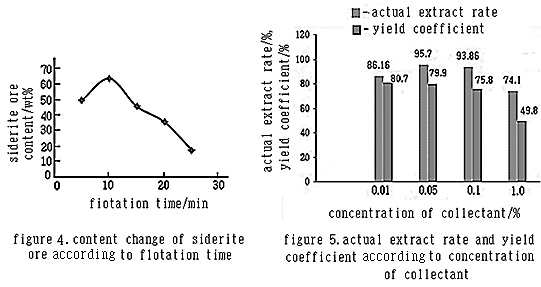

This collecting agent has the property of foaming. The use of this reagent decreases the price a lot in comparison with the use of Oleic acid.

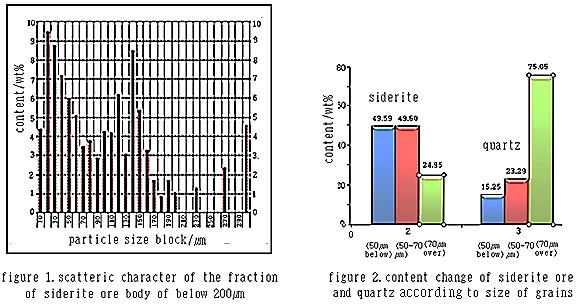

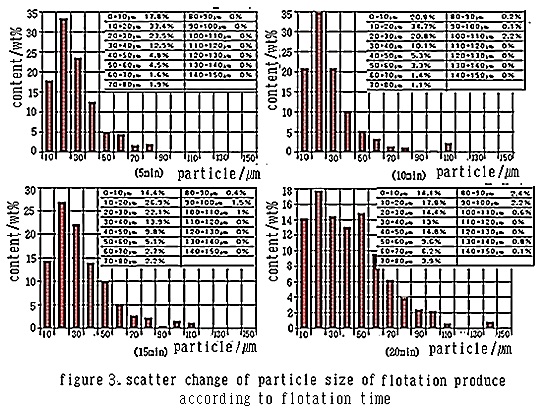

So far siderite is considered as difficult for floatation concentration.

However, it is possible to use floatation concentration for siderite.

Floatation concentration for siderite is simple in process and favorable for the protection of earthly warming and it can save much energy. And it can widely and effectively be used in various fields of national economy. While magnetic roast-magnetic concentration uses siderite only as the raw material for iron by converting it into FeC03, floatation concentration for siderite is possible to be used not only for the production of iron but also for the materials of many others. For instance, we can save respectively 130, 000tons of anthracite and oxygen (99.5%) in a year when concentrated ore is used as 30% of supplement gasification for the air-flow coal gasification furnace and we can get 80,000tons of magnetic iron in ash (60, 000tons/year, being turned into converted iron). And we can also use 4% of concentrated ore for the production of cement, 85% for casting by way of siderite egg coals, 22% for carburization, 8% for iron-nickel electrode for cast iron, and we can also use it for other material science.

The research group is still strengthening studies for the more effective operation of floatation concentration for siderite by converting it into a thoroughly localized reagent system.