The respected Comrade

"We should make it our major thrust to develop such core, basic technologies as IT, nanotechnology and bioengineering, along with such pivotal and beneficial scientific and technological fields as new materials and energy, space and nuclear technologies, and concentrate our efforts on them."

Alkyd resin (AR) has been widely used for paint applications due to its fine gloss retention and heat resistance but it has now a tendency to be replaced by polymers such as epoxy or polyurethane etc. which have superior property. Nevertheless, AR is less expensive and bio-based, so it is extensively being applied and developed.

Nowadays, linseed oil, dehydrated castor oil, tobacco seed oil, etc. have been used as the important bio-based chemical feedstock to modify alkyd resin with high level of oil length, which results on high content of bio-based raw materials in the world. AR with higher oil length is easier to be applied and has more compatibility of pigment, flexibility and higher water resistance, while gloss, hardness and viscosity are lowered, and alkyd resin modified with rosin has higher curing and hardness.

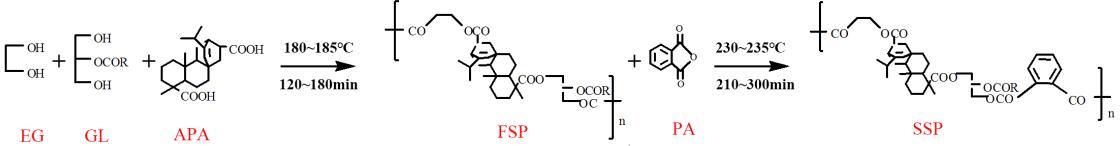

Rosin acid(RA), a compound of different resinous acids, contains abietic acid as a main component, which is polycyclic compound and is used as a monomer for synthesis of polymer by changing dibasic acid through Diels-Alder reaction with different organic acids which have unsaturated bond. Newly, acrylic pimaric acid(APA) which is synthesized from reaction of RA with acrylic acid(AA), is used as raw material for synthesis of polyesters, polyamides and unsaturated polyesters so that it enhances curing and hardness, decrease their costs.

Recently, researchers of High-Tech Research and Development Center at

Alkyd resins (AR) of 65% oil length were prepared with dehydrated castor oil (DCO), glycerol (GL), ethylene glycol (EG), acrylic pimaric acid (APA) and phthalic anhydride (PA) by using a three-step alcoholysis-polyesterification method. APA was synthesized from Diels-Alder reaction between rosin acid (RA) and acrylic acid (AA). First the alcoholysis was performed with GL and DCO. And then APA and EG were added and reacted at 180℃ until an acid value of 8 mg KOH/g. Then PA was added and reacted at 230℃ to yield HOAR.

Structures of the alkyd resin were investigated by FTIR and 1H NMR spectroscopy. Five different HOARs having APA content of 3%, 6%, 9%, 12% and 15% were prepared and physicochemical characteristics of the resins were compared to that of reference alkyd resin. It was shown that HOARs having APA content of above 9% have good physicochemical properties such as gloss, pencil hardness, impact strength, acid resistance and alkaline resistance.

The results of this study were published in SCI paper entitled "Synthesis and characterizations of high oil length alkyd resin with dehydrated castor oil and acrylic pimaric acid" (https://doi.org/10.1016/j.cplett.2022.139934) in Journal "Chemical Physics Letters" (2022, Vol. 805, No. 139934).